On November 30, 2020, the JWF1580 super-long intelligent spinning frame developed by Jingwei Intelligent Textile Machinery Co., Ltd. ("Jingwei Intelligent Company") successfully passed the scientific and technological achievement appraisal in Weiqiao Textile Company Limited, Shandong.

Through on-site demonstration and acceptance, the expert group agreed : “JWF1580 super-long intelligent spinning frame has independent innovation and solves the technical problems of the domestic super-long spinning frames. The technology has reached the world's advanced level and has an extensive market prospect, good promotion value, and considerable economic and social benefits. We suggest a further increase in promotion efforts.”

01 Over-length up to 1824 spindles

- Design spindle speed is 25000 r/min

- Standard design spindle number is 1824 spindles

- The super-long spinning frame can save 20% of the floor space

- Energy consumption is 15% less than the existing models

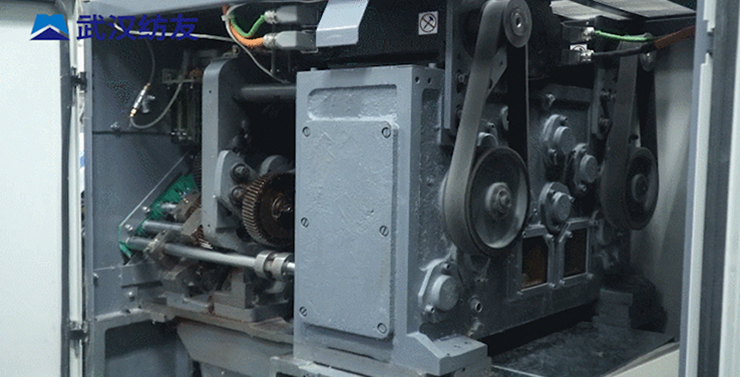

02 The technology of longer frame, high-speed, stabilizing the rack

- The curve superimposed on the integral central wall panel

- Adopted new large-span structure of 2520mm, I-shaped, high precision keel

- Symmetrical technology ensures the straightness of the spinning frame

03 Fast-installation technology

- Quickly positioning pin and hole ensures the installation fast and accurate.

- The V-groove of the wall panel in the large column enables precise positioning of the large column, fast assembly and maintenance-free

04 Synchronizing driving technology in the central of bottom roller

- The synchronizing driving technology realizes the sectional drive of roller

- Drive synchronously 1/3 of the roller improves the resistance to torsion to operate the roller at lower torque

05 Heavy load ring rail technology

- Two-stage reduction heavy-duty worm gear box solves the bearing capacity problem of super large torque worm gear box

- New ring rail lifting system and the new eccentric mechanism can control spinning tension to reduce yarn broken-ends

06 Electronic twisting and drafting techniques

- Digital encoder tracking technology realizes precise control of the spindle and roller movements

- To produce high quality yarn and keep the breakage rate as low as possible

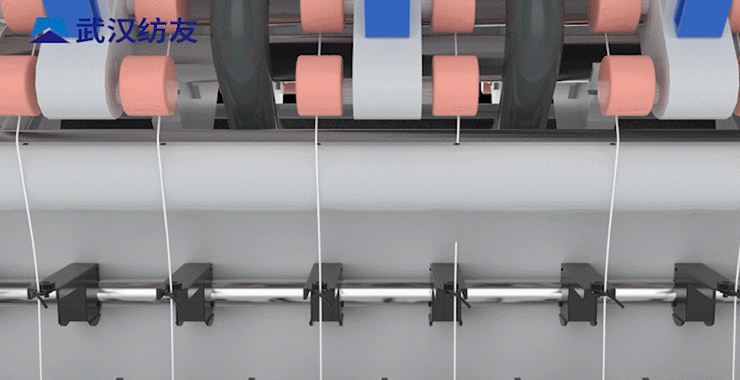

07 Bilateral cotton suction system

- The bilateral suction system reduces the loss of negative pressure and solves the problem of balancing negative pressure of cotton suction

- This technology can reduce energy consumption of cotton suction by 15% in a single spindle process

08 Centralized waste collection system

- Centralized waste collecting device works in coordination with the air conditioning and dust filter system in the workshop

- Realizing the automatic centralized collection of waste promotes the process of unmanned spinning factories

09 Accurate and fast collective doffing technology

- Air-frame lifting and inside-outside pendulum technology can achieve accurate and fast doffing

- with the automatic doffing system, the shortest doffing time can reach 2.5 minutes.

10 Electronic twisting and drafting synchro-control technique

- Common DC Bus technology realizes that multiple motors stop synchronously when power-off or short duration voltage variation happens.

- It ensures the yarn quality and yarn reserving rate of auto-doffing

11 Single spindle detection and roving stop system

- It realizes real-time detection of the traveler situation of each spindle under the spinning condition

- It realizes the functions of broken-end statistic and analysis, twist monitoring, etc. which reduce labor number and lighten the labor intensity

- When the yarns break, the instant stop of roving feed can save roving waste and ensure the safety of unattended equipment

12 Intelligent electrical control system

- The intelligent electrical control system can realize the optional functions of slub yarn, individual spindle detecting, the roving-feed stopping, etc.

- It also has the function of storage technological parameters, yarn breakage statistics analysis, twist monitoring, fault statistics, remote operation and maintenance interface, etc.

So Far, the super-long intelligent spinning frame has been chosen by multiple major projects in China and abroad, such as Daiyin Textile Malaysia Company, Yu Feng Group, Hubei DeYongSheng Textile Co., Ltd., Bobur M&F in Uzbekistan, etc. The total sales volume is more than 300 sets of 600,000 spindles. Now, JWF1580 is highly recognized by users and has become an ideal choice for mid-to-high-end customers to upgrade.

For the company, the success in R&D and batch use of the JWF1580 super-long intelligent spinning frame formed a complete series of spinning frame product patterns. Substantial breakthroughs in several key technologies also demonstrated Jingwei's technical strength and further enhanced Jingwei's market share and core competitiveness of the spinning frame. In terms of industry and at the national level, JWF1580 solves the technical problems in the super-long spinning frame field in China,improves the intelligence technology level of domestic spinning frames. Moreover, it has become a competitive high-end intelligence spinning frame in the international market.

中文

中文